|

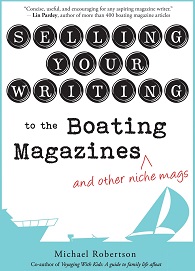

Shortly after arriving back in Ajo from Fiji,

we took a quick trip down to Mexico (the

border is only 30 miles away). Sunsets like

this were our reward. |

After

seven years that stand as among the most enriching and illuminating of our

lives, we’ve got an end game planned.

After

we return to Del Viento in Fiji in early

June, we’ll haul the old gal and paint the bottom and re-grease the MaxProp.

Then we’ll check out of Fiji and head west for Vanuatu. Uncharacteristic of

this crew, we won’t spend more than a few weeks there before setting sail for

New Caledonia. Then, still on a delivery-like schedule, we’ll raise anchor soon

after arriving and point our bow for Australia, likely making landfall in

Brisbane. At this point, we’ll pack our things, clean Del Viento, put a For Sale sign on her, and fly back to the States to

build a new life on land.

We’ll

be back in time for Eleanor to start high school—she’s 14 for goodness sake,

she’ll be 15 this fall. Frances is 12. My kids have spent the bulk of their

lives so far as sailing vagabonds.

In

fact, this has been such a unique and vibrant and recent chapter in my life

that it feels like the bulk of my life. Seven years on a tiny private island

with my family. The beauty and magic of that, especially in retrospect, is

something I’ll always be grateful for.

My

friend Wendy Mitman Clarke once wrote that she doesn’t like the term cruising

lifestyle, she wrote that it feels smarmy, perhaps illicit. I see her point,

but it leaves me with a loss of words when trying to describe the way we’ve

lived as cruisers. Because it is a lifestyle, and one so removed from what is

common, from how I grew up, for example, that living the cruising lifestyle

imparted an identity. To most family and friends and acquaintances, we’re the

only ones they know living like we do. For a decade, it’s been who we are,

first as the family with the crazy plans and then as the family enjoying the

cruising lifestyle.

The

cruising lifestyle has suited us. It’s made us happy and rich, though not

financially, but in many of the ways in life that matter. As the end draws

near, we don’t have a smidgen of regret for deciding to cast off as we did. For

that I’m grateful. In fact, I remind myself that most families don’t even get

the short sailing adventure we still have ahead of us.

Of

course, things could be different, right now regret could be the primary

feeling about our cruising lives. On more than one occasion, only blind luck saved us from a very

different reality. But that’s the case no matter the path we choose in life. No

question I’d rather be on a path that challenges and provokes than one that

pacifies. The cruising lifestyle taught me the meaning and value of the idea

that life is short.

Which

begs the question: why stop?

I

think the reasons are different for each of us.

I

feel like I have no choice but to stop, regrettably. For the past year, my gig

as Good Old Boat editor has been more

than a full-time job, and one that requires regular Internet connectivity. Both

those demands are at odds with the family cruising lifestyle. Upon accepting

this role (the previous role as managing editor was half-time and not such a

conflict) we cancelled plans we’d had to head north for Japan, something that

was upsetting to all of us. (Even getting to Australia this year will be a

challenge, in terms of juggling work.) But, I need an income and at least this

career provides an enormous amount of flexibility and mental stimulation and

genuine interest. I’m fortunate that have successfully navigated a mid-life

career change, and to have put it off long enough to have the time on the water

we did.

Windy

wasn’t ready to stop, but realized we must. And now, having gotten her head

around the idea, she’s among the most enthusiastic stoppers of us all. No

regrets, we’ve had a good run, time to move on. Let’s plant a garden!

Eleanor

would have gladly retired from the vagabond sailing life a year ago. She wants

permanence. She wants to be in a setting where she sees more people her age and

sees them regularly. She wants to find her tribe. I don’t understand this. I’ve

told her how miserable I found high school, but she’s got a mind of her own and

that we can’t ignore.

Frances

is content to keep cruising, just as we have, indefinitely. I guess she and I

are of like mind that way, but I’m part of the reason we’re stopping, and she

is not. I feel badly for this, but I reason that she’s the kind of kid who will

be happy anyplace and she’s extraordinarily lucky to have had the time she’s

had. I also feel that part of her reticence to leave the cruising life behind

is tied to the fact that it’s really all she knows. Frances remembers very

little of the house in Washington, D.C., the house she was born in and that we

left seven years ago. She’ll be fine, but she’s not ready to leave the party.

So

we’re almost done.

Going

back to the identity thing, there is a nagging feeling that when we leave

Australia, I’ll be leaving part of who I am behind. We’ve become those people

who live on a boat and travel. I think the molting that’s coming will be good.

“I live on a boat and travel,” was too easy. It begged questions for which I

had pat answers guaranteed to impress. I rarely had to explain or define myself

further. It was my skin and it was comfortable. Our cruising lifestyle was the

why of everything. When it’s over, I'll be just another guy who lives in a house. I won’t fall back on “I used to live on a

boat and travel.” Perhaps that’s the new

journey ahead, a challenge to find the life ashore that provokes.

--MR

|

| View from a road in Fiji. |

|

Eleanor aboard Del Viento opening the package of nori

in preparation for assembling her sushi. We had dinner

together as a family (at a table) nearly every night of our cruising

lives. It's something that we take for granted and a practice

we'll maintain in our land lives. |

|

Here we are at the Nadi airport. Windy's face says it all, it was grueling

to get to this point. We brought a lot of stuff back with us this time--one

more load like this from Australia this fall, and everything else goes with

the boat. |